Mining

Empowering Unmanned Mining Trucks to Achieve Scaled Operation

The mining operation environment is harsh, and it has long faced issues such as safety production and difficulties in recruitment. Driven by policies and the development of autonomous driving technology, the application of unmanned driving in mines has become an inevitable trend for intelligent mine operation.

Seyond’s mining solution is based on high-performance image-grade LiDAR, providing high-precision long-distance detection capabilities and superior dust penetration abilities. It is not affected by the dust and direct sunlight in the mining area. The output of high-quality structured point cloud data facilitates algorithms, helping improve operational efficiency while identifying risks early to ensure operational safety. It empowers unmanned mining trucks to achieve scaled operation.

Falcon K

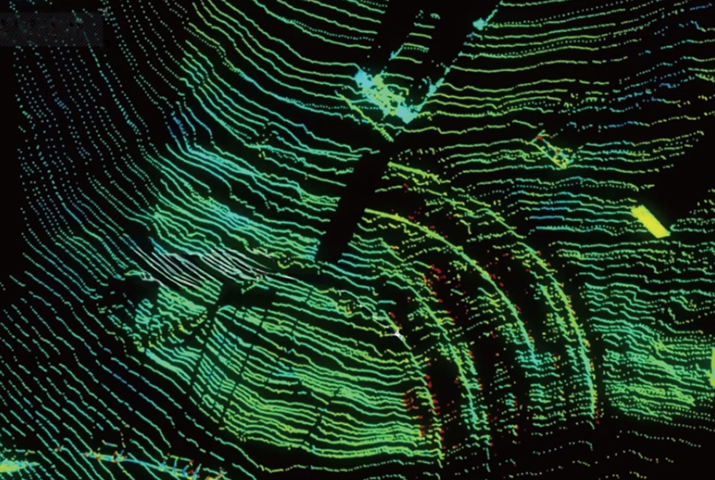

Mining environments, especially coal mines, are often characterized by harsh conditions, including flying sand, rolling stones, and unstable slopes prone to landslides and collapses. Seyond’s high-performance, image-grade Falcon LiDAR offers exceptional resolution and long-range detection capabilities. It accurately identifies obstacles such as curbs, rut lines, and falling rocks, enabling mining fleets to detect potential hazards early, ensuring safer and more stable operations in complex environments.

Robin W

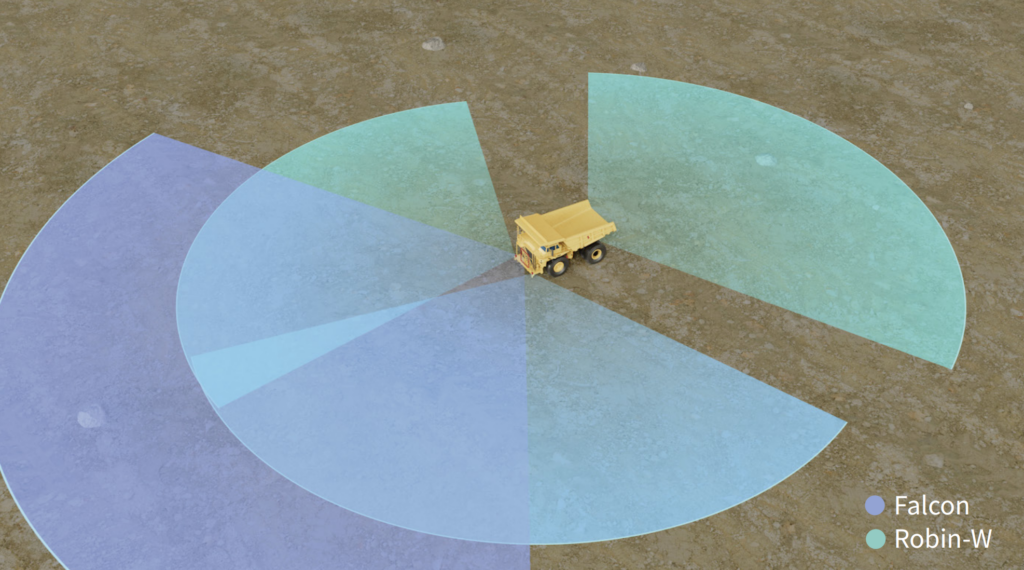

Robin W LiDAR, built for automotive-grade reliability and full industrial-scale production, provides continuous, stable, and precise detection in all weather conditions. Whether in extreme cold, heat, dust storms, direct sunlight, or under intense vibrations, Robin W ensures uninterrupted 24/7 operation of autonomous mining trucks. Its wide field of view empowers real-time monitoring and safety, even during the “safety officer off-vehicle” operation periods in mining areas.

Competitive Advantages

Unaffected by Light Interference

Excellent Dust Penetration Ability

All-weather High-precision Detection

Automotive-grade Reliability

Fully Industrialized Production Line for Mass Production

Ultra-high Resolution

Coal mines are often located in environments filled with flying sand and rolling stones year-round. The mine pit slopes and waste dump slopes formed by open-pit mining are prone to landslides and collapses due to the influence of geological structures, slope rock bodies, and engineering activities. Seyond’s high-performance image-grade LiDAR has extremely high resolution detection capabilities. It can accurately detect obstacles such as curbs, rut lines, and falling rocks, helping the fleet to discover potential dangers earlier and more stably under complex conditions. This provides more ample calculation and execution time for the autonomous driving system, ensuring the safe operation of unmanned mining trucks.

Ultra-long Detection Range

Mining trucks requires the perception system to achieve longer-distance detection and discover obstacles such as rocks and falling rocks earlier. This provides timely and accurate decision-making support for planning safe routes for the trucks, avoiding larger economic losses. Seyond’s high-performance image-grade LiDAR has ultra-long detection range, substantially enhancing the perception range of the unmanned fleet.

Strong Environmental Adaptability

The mining work environment is dusty, foggy, and often experiences rainy, snowy weather, and extremely low temperatures, with rugged roads filled with sand and gravel. Seyond’s high-performance image-grade LiDAR can withstand temperatures as low as -40 degrees and can also withstand the long term severe vibrations in the mining area. It reduces the manual requirements for key production links such as stripping, loading, unloading, and transportation in open-pit mines, achieving efficient collaboration between production links.

Deployment

High-performance Front-view and Wide-FOV LiDAR Solution

Ready to Learn More?

At Seyond, we’re pushing the boundaries of LiDAR technology to shape a smarter, safer, and more connected future. Discover how our cutting-edge systems are revolutionizing industries and explore how we can help you achieve your vision.