Ports

Automation, Digitization and Intelligence of Port Industry

With the development of port industry, automation, digitization, and intelligence have become new drivers for port development. In recent years, the scale of terminal operations has been expanding constantly, presenting many challenges to production management at the terminal, such as increasing costs, continuous safety risks, insufficient staff capabilities, and lack of production efficiency. These are widely recognized industry problems that urgently need automated and intelligent means of production and management.

Seyond‘s port solution is based on high-performance image-grade LiDAR, providing 24-hour, all-weather, high-precision cargo scanning and container positioning, helping increase operational efficiency at shore and yard. It assists autonomous trucks at the port area to better avoid obstacles in front and provides positioning guidance, ensuring safety and efficiency while reducing operating costs.

Falcon K

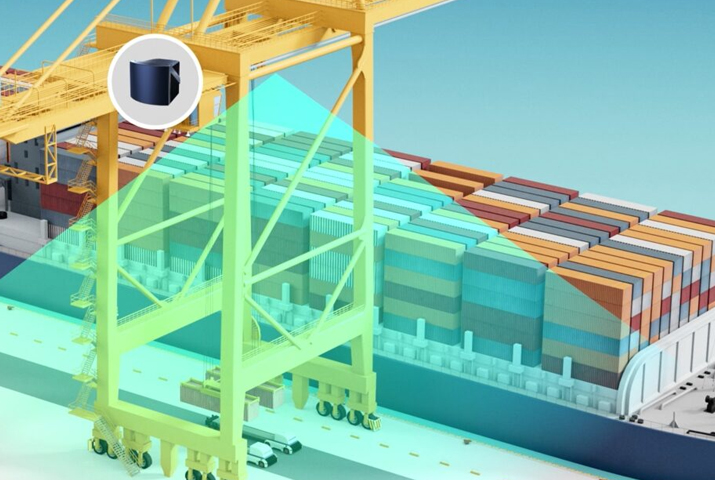

Installed on the shore, Falcon LiDAR provides real-time data on vessel distance, speed, heading angles, and 3D dimensions during berthing and departure. By delivering precise safety insights and early warnings, it enhances docking efficiency and reduces the risk of accidents.

Robin W

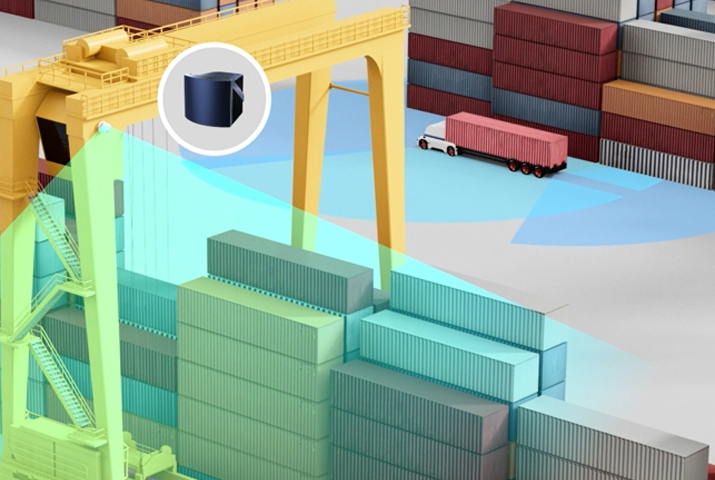

Integrated with intelligent equipment control systems, Robin W LiDAR enhances automation in cargo operations, container handling, and grab ship unloading. It assists crane operators in maneuvering containers smoothly and efficiently while preventing vessel instability. Installed on shore and yard cranes, Robin W optimizes operational efficiency, ensuring safer and more precise logistics handling.

Competitive Advantages

All-weather Accurate

Image-grade Ultra-high Resolution

Automotive-grade Reliability

Fully Industrialized Production Line for Mass Production

Multi-scene Flexible Adaptation

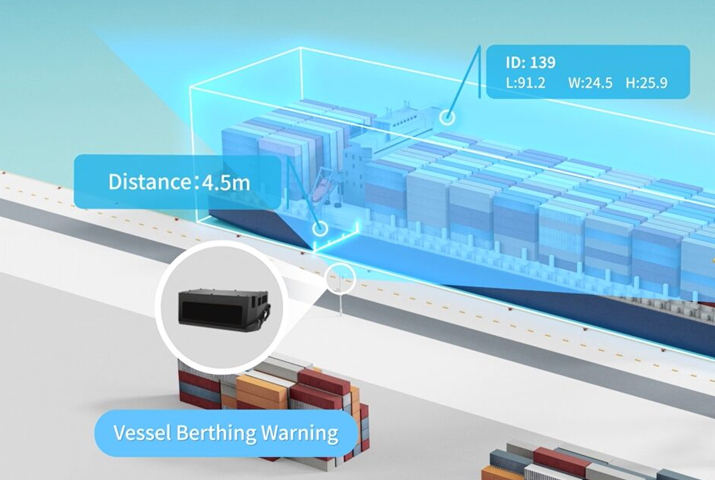

Vessel Berthing Warning

Installed on the shore, the LiDAR assists understanding real-time information such as distance, speed, heading angle, and three-dimensional size of the ship during berth and departure. It provides safety suggestions and early warning information, preventing collisions and enhancing berth operational efficiency.

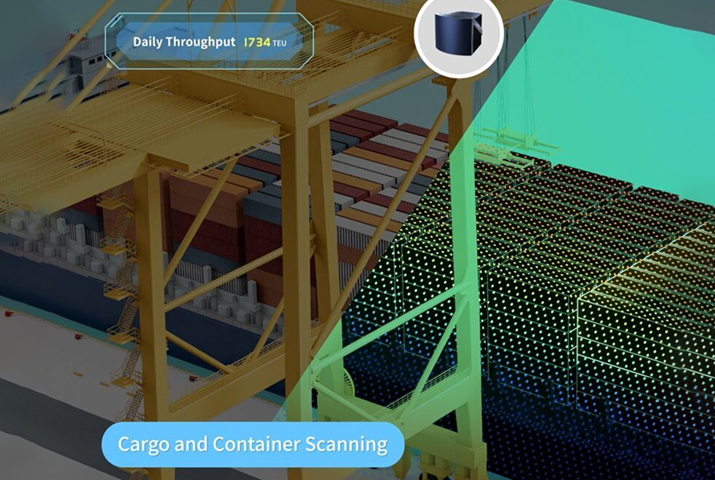

Cargo and Container Scanning

Fixedly installed on the shore crane, the LiDAR obtains real-time high-precision three-dimensional information of the ship and cargo. Working with the intelligent equipment control system, it helps crane operators to handle containers more smoothly, efficiently, and scientifically, preventing ships from capsizing.

Automation for Grab Ship Unloaders

Installed on the shore crane, the LiDAR provides high-precision three-dimensional point cloud information to real-time perceive the relative positions of target containers, lifting appliances, shore cranes equipment, and unmanned container trucks. It assists remote control shore cranes to more accurately grab and place containers, while guiding autonomous driving trucks to park more accurately, greatly improving the loading and unloading efficiency.

Autonomous Driving Trucks

Four LiDARs installed on the truck can achieve 360° coverage around the vehicle, effectively perceiving obstacles around. With automotive-grade reliability, it provides 7x24H working capability and strong environmental adaptability, ensuring safety, controllability, orderly, and high efficiency of operations in complex scenarios.

Cargo Operation at Container Yard

Installed on the yard crane, the LiDAR can obtain real-time high-precision three-dimensional information of the cargo. Working with the intelligent equipment control system, it helps avoid collisions when grabbing and placing containers.

Automated Container Handling

Installed on the yard crane, LiDAR provides high-precision three-dimensional point cloud information, assisting in real-time perception of the relative positions of target containers, lifting appliances, yard crane equipment, and transport vehicles. It assists automated yard cranes to accurately grab and place containers, while guiding autonomous driving trucks to park more accurately, achieving automated loading and unloading operations in the yard.

Ready to Learn More?

At Seyond, we’re pushing the boundaries of LiDAR technology to shape a smarter, safer, and more connected future. Discover how our cutting-edge systems are revolutionizing industries and explore how we can help you achieve your vision.